Introduction

Vietnamese plywood has gained recognition for its competitive advantages in the global market, with continuous development and improvement over the past 20 years in Vietnam. The plywood manufacturing industry has become one of the key industries, a leader in exporting goods and wood products.

Main Material

Vietnamese plywood is a sheet of material made from many layers of natural wood sliced (Acacia, Magnolia, Eucalyptus, Stryvax…) about 1.2-2 mm thin. These layers of wood are arranged perpendicularly in the direction of the wood grain of each layer, then pressed together under high temperature and pressure with the participation of adhesives, usually Phenol or Formaldehyde glue. The surface of Plywood could be Bintangor, Okoume, Film Faced…

Competitive advantages

- Low price

The competitive pricing of Vietnamese as well as Kego’s plywood is a result of factors such as abundant raw materials, cost-efficient labor, economies of scale, modern production techniques, market dynamics, and strong domestic and international demand. This combination of affordability and quality has solidified Vietnamese plywood’s position as a preferred choice in the global plywood market.

The Packing and Commercial Plywood in Vietnam is the most reasonable price while being produced widely and professionally through nearly 20 years of development.

- High Durability

Kego’s plywood is often produced using high-quality timber sourced from the country’s abundant forests. The selection of quality raw materials is the foundation for durable plywood.

With Kego’s Commercial Grade, we assure you that this plywood can be cut by cutting machines, CNC, or nailing and cause no damage to the core, especially with no warping, tearing, or splitting. Thanks to the excellent quality of Glue we’ve developed for many years.

- Perfect moisture

Kego typically controls the moisture content of the wood used in production to ensure it falls within the optimal range. We achieve this through a carefully controlled drying process and manufacturing techniques from sun drying, and machine drying to appropriate hot press settings. The moisture content of Commercial Plywood is usually from 6-14%.

- Quality Assurance

Kego is committed to maintaining high-quality standards. We invest in quality control measures, ensuring that the plywood they provide meets industry standards and customer expectations. This commitment to quality translates into reliable and durable products.

When buying plywood from Kego, you will receive plywood with exactly the same quality you have seen in our factory. Because we believe that reputation is the only and most sustainable bridge of business.

- Excellent customer service

Customer service excellence extends beyond the sale. Kego offers after-sales support. If you have questions or require assistance after receiving your plywood, they are there to help, ensuring a positive overall experience.

We have a strong commitment to customer service and valued customer feedback. Kego uses it to make improvements in its processes and products, ensuring an ongoing positive experience for all customers.

MAIN PRODUCT OF KEGO’S PLYWOOD:

- Commercial Plywood (AA/AB/ABC Grade)

- Packing Plywood (AB/BC Grade)

- Container Flooring Plywood (AA/AB Grade)

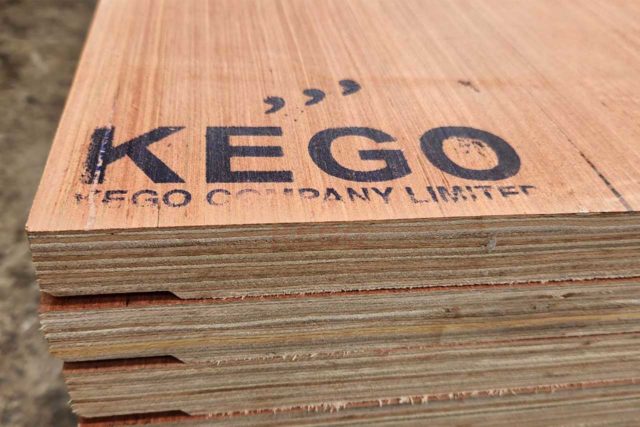

kego plywood

- Film Faced (Shuttering) Plywood (AA/AB Grade)

CONTACT US

Call us: + 8424 3222 2333 – +84 97 999 5346 (Whatsapp)

Email us: sales@kego.com.vn

Location: R.603 Kim Anh Building, Lane 78, Duy Tan Street, Cau Giay District, Hanoi City, Vietnam