There are many ways to distinguish LVL pallet types, but you can rely on 3 main factors: style and design to classify pallets. Below are the types of pallets classified according to the above 3 factors.

Sorting pallets by style

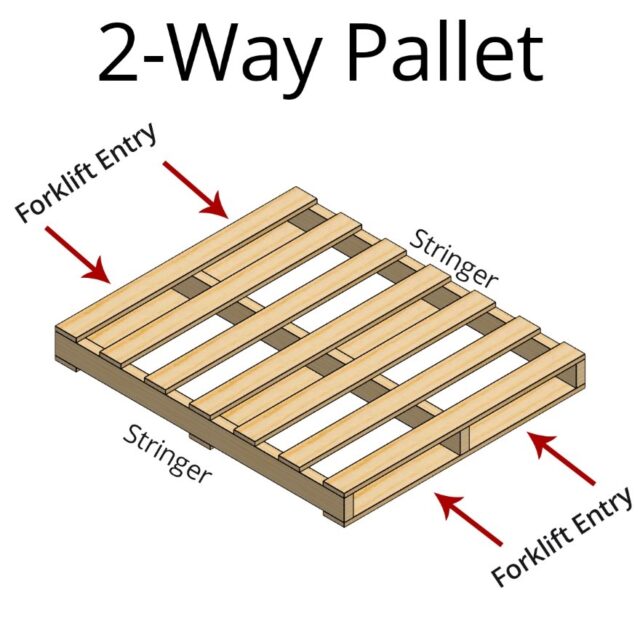

A simple way to distinguish pallet types is by the number of pallet entry points. Here is a summary of pallet types by the number of input points:

Two-way entry: One way pallet (with 2 entrances for forklift)

Four-way entry: 2-way pallet (with 4 entrances for forklifts)

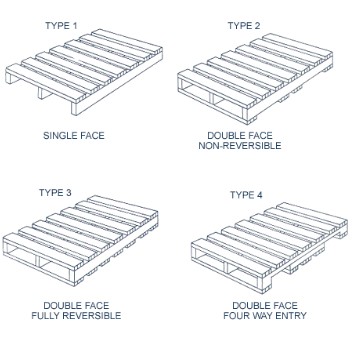

Open Deck Pallet: A type of pallet on the floor surface with gaps. This type of pallet will be lighter and less expensive than other types of pallets. However, they cannot transport smaller items as such goods may fall through gaps.

Solid Deck Pallet: Is a type of pallet on the surface is a smooth flat surface, not rough, no gaps. Pallet surface can be made of wood, metal, plastic, easy to clean and transport goods. These types of pallets are often used to transport small goods, avoid them falling during transport like Open Deck Pallets.

Double Face Pallet: A type of pallet with 2 sides (top and bottom) that can be used. The advantage of this type of pallet is that it supports the load capacity and the weight is also distributed more evenly with the contact surface.

Sorting pallets by design:

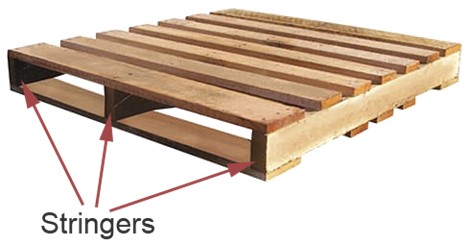

Based on the design, pallets are classified into 2 main types: block pallets and stringer pallets.

+ Block pallet (hunchback pallet): is a type of pallet made of 9 blocks with, with special structure – forklift can access 4 different pallet dimensions.

+ Stringer pallet : is a 2-way pallet, the two forks of a forklift or pallet jack can access goods from 2 directions, which are 2 sides. Their sizes will be flexibly designed to fit your inventory.

In general, LVL get many advantages over sawn milled lumber:

- LVL can be made from various veneer materials poplar, pine, acacia, eucalyptus, rubber, …

- The added durability of being an engineered wood product means LVL is less prone to shrinking or warping. LVL can also support heavier loads and span longer distances than normal timber

- LVL can be used wherever sawn timber is used however one of the main advantages is that it can be manufactured to almost any length, restricted only by transportation to site

- LVL provides a cost-effective and sustainable packing material, delivering high structural reliability and strength

LVL got many advantages to be used in pallet, but other than that, this type of LVL pallet can break under heavy loads, get damaged or wet, which can be vulnerable to insects. Depending on the warehouse with the characteristics of goods, warehouse space and racking system, you can choose the right type of LVL pallet.