Since the process of containerization started taking place before World War II (1955), the container has continuously developed in terms of structure, becoming a standard unit (usually assembled according to ISO standards). Conformity in freight transportation has become the main factor driving the development of container shipping and multimodal transportation worldwide. So how is a container structured to have such a wide application in transporting goods? Let’s explore this issue with KEGO

According to the International Organization for Standardization (ISO), a container is a transport tool with a fixed and durable shape that can be used many times, with a special structure to facilitate loading, unloading and transshipment at the same time. with a volume of not less than 1m3. There are 7 types of containers in which the most complete departmental container structure includes:

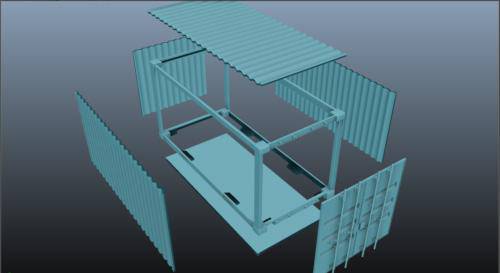

CONTAINER FRAME

The frame is rectangular in shape, made of stainless steel with four corners (corner post); 2 bottom side rails; 2 roof rails (top side rails); 2 bottom cross members; 1 crossbar on the front (front top end rail); 1 crossbar on the rear (door header)

CONTAINER FLOORING PLYWOOD

The bottom and floor are stainless steel horizontal beams (undercarriage) connecting the container frame to create a solid bearing block for the entire container. Container decks are usually mounted with 28mm thick plywood or slats for transporting a wide range of goods, which are mounted with crossbars at the bottom of the container for easy assembly and replacement. Currently, Kego Company Limited is supplying a good and strong quality of the container flooring plywood to use in repairing or new installation of the container, it’s made from 100% eucalyptus core and adding the film faced (Optional) or Keruing/Gurjan surfaces with international quality standards.

ROOF PANEL

Roof panel is made of sheet steel, aluminum or plywood covered with glass fiber reinforced plastic, parallel corrugated

SIDE WALLS & FRONT END

- Side walls are corrugated steel sheets like roof panels covering both sides of the container.

- The front end wall is steel plate, corrugated in square blocks

- Rear end wall and door and corner fittings The structure of the back of the container consists of 02 separately designed steel plates. Container doors can be opened to the outside at an angle of 270 degrees.

- Angle assembly (also known as corner casting) is made from steel, welded to the upper and lower corners of the container, which is the part that locks (twistlock) of lifting equipment (cranes, forklifts). or lashing device hooked up during the lifting, stacking, or lashing of the container.

Through this article, we hope that you can have more information about the common structure of departmental containers. In particular, the container flooring plywood is one of the inseparable parts, Kego is specialized in this Container Flooring Plywood since 2016 until now and we have various grade for you: T5/T6/T7 grade.

Feel free to contact us right now: